- Get link

- X

- Other Apps

Week 4

[Achievements]

Day 22 -->

Electronic Production:

1. Electronic Components

1. Electronic Components

- 1. Got familiarised with diodes, Leds, Capacitors, Resistors, ICs, Zeners etc. by our instructor

3. Roland's PCB Milling techniques

4. Populating of board

5. Soldering

6. Programming

<-- Week 4

Day 22

[ Preparing Files ]

Day 23 -->

1. Troubleshooting Laptops of my peers installing Ubuntu

2. Editing my Website

After a very informative Recitation with Dr. Neil, I sat for an hour or two to think of ideas regarding my assignment and how i plan to go about it. Went through softwares suggested by other fabbers like Flatfab and also different types of laser machines like waterjet, iron cutting etc.

EDITING

ORIGINAL FILE IN PHOTOSHOP

EDITING

MODIFYING THE TRACE PNG

EDITING

SHAPING THE CUT FILE

EDITING

ADDING A KEYCHAIN HOLE

EDITING

CLEANING THE PNG

EDITING

FINAL CUT FILE

<-- Day 22

Day 23

[ Setting up Modela ]

Day 24 -->

1. Learnt how to mill using roland modela

2. Tried milling by myself in the presence of our instructor Suhaas and Suyog.

Today, its Vigyan Ashram's holiday as its their Village yatra (journey) where all the people belonging to that village meet each other coming from different places, pray as community and invite others to their home for lunch and dinner. So I was invited to one of our instructors place which had a very beautiful and heritage architecture, ate very tradional Vegetarian food. On this occasion they also have faire as community.

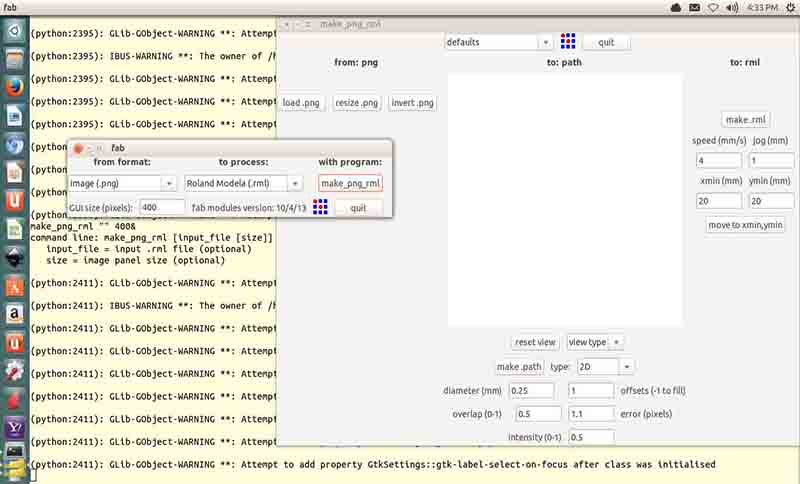

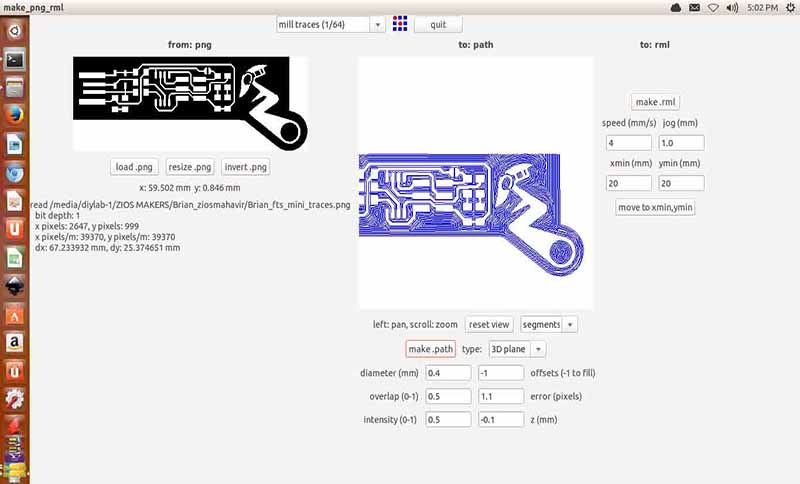

SUDO FAB

ENTERING PASSWORD

SUDO FAB

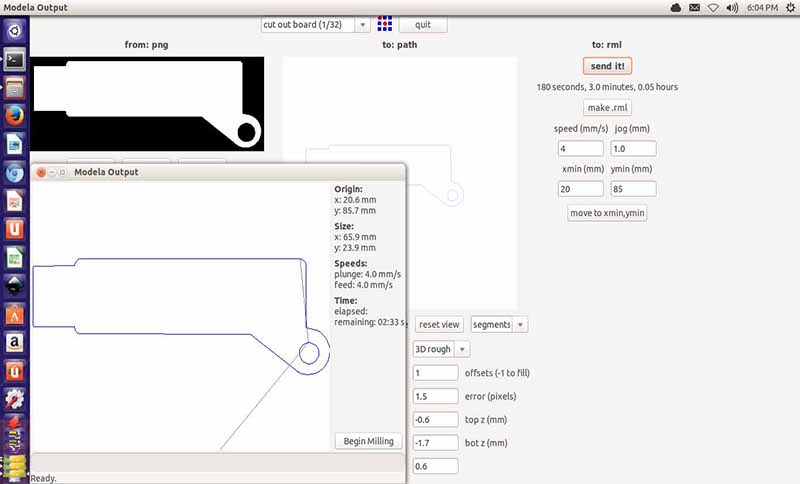

ROLAND MODELA AS .RML

SUDO FAB

LOADING MY PNG FILE

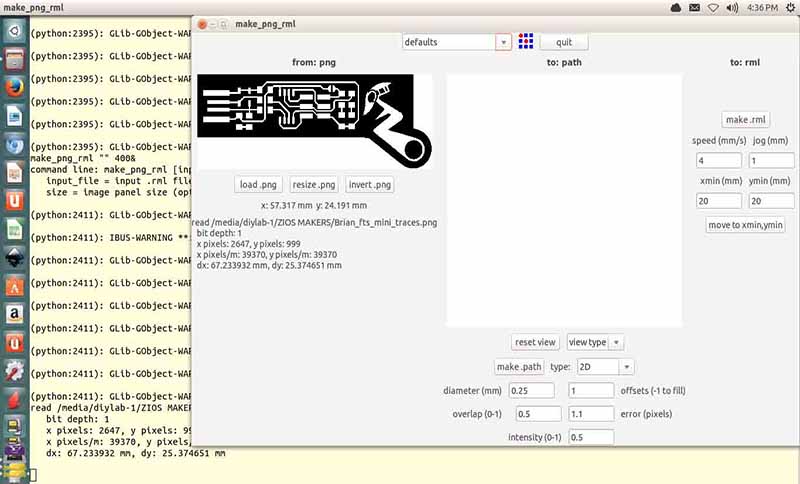

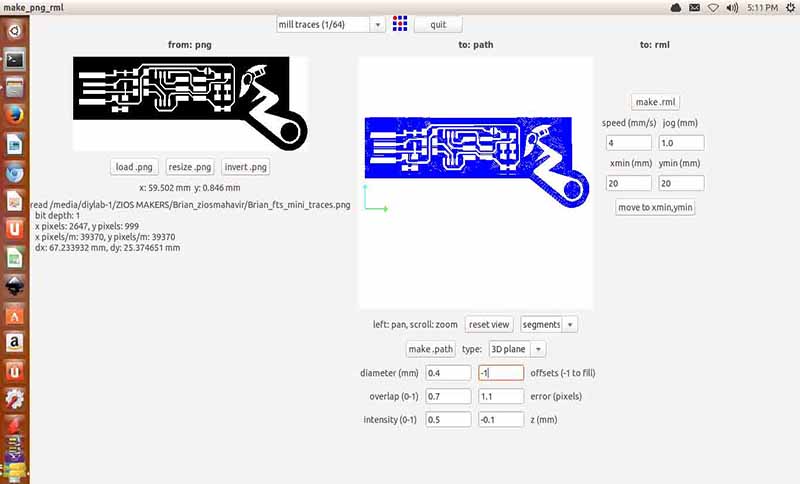

SUDO FAB

SETTING OFFSET TO -1

SUDO FAB

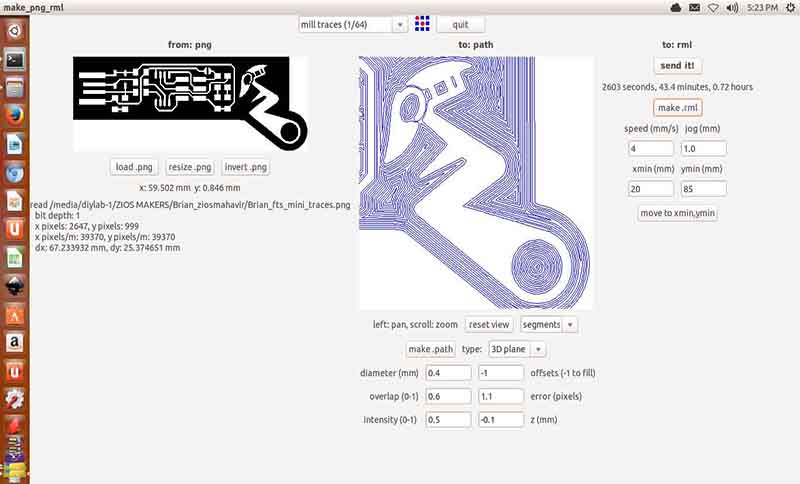

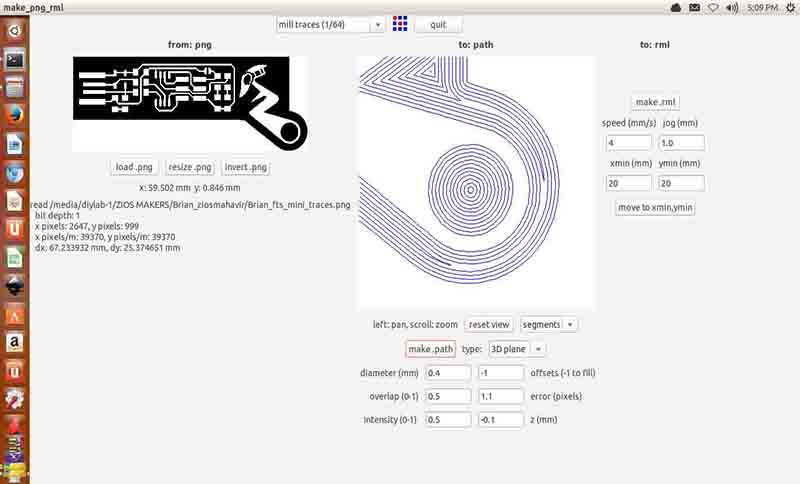

MAKE PATH ON 1/64 BIT

SUDO FAB

0.5 OVERLAP WONT BE ENOUGH

SUDO FAB

CONFIRMED ON ZOOMING IN

SUDO FAB

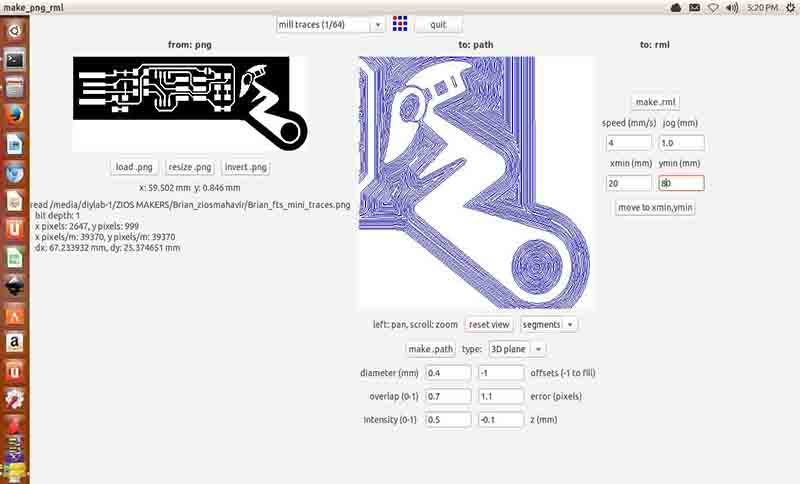

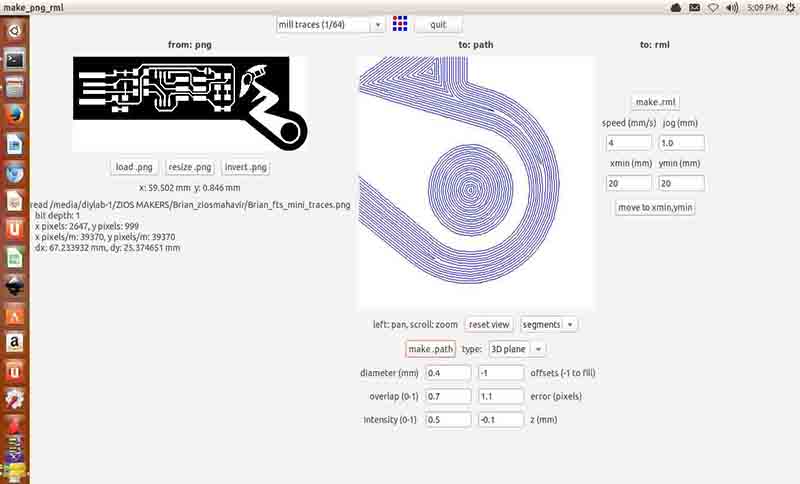

0.7 OVERLAP WILL GIVE RESULTS

SUDO FAB

CONFIRMED ON ZOOMING IN

SUDO FAB

LOADING CUT PNG

SUDO FAB

SELECTING 1/32 BIT

SUDO FAB

CONFIRMED PARAMETERS

<-- Day 23

Day 24

[ Fun moments with Modela]

Day 25 -->

Today is Saturday :

1. Had fun with the modela's broken cover with tape on its sensor

2. No blower to blow the dust off. Blowing with my mouth making sure not to inhale it back

3. Perfect milling of my board after few trials and understanding.

1. Had fun with the modela's broken cover with tape on its sensor

2. No blower to blow the dust off. Blowing with my mouth making sure not to inhale it back

3. Perfect milling of my board after few trials and understanding.

Today, its Vigyan Ashram's holiday as its their Village yatra (journey) where all the people belonging to that village meet each other coming from different places, pray as community and invite others to their home for lunch and dinner. So I was invited to one of our instructors place which had a very beautiful and heritage architecture, ate very tradional Vegetarian food. On this occasion they also have faire as community.

Today, its Vigyan Ashram's holiday as its their Village yatra (journey) where all the people belonging to that village meet each other coming from different places, pray as community and invite others to their home for lunch and dinner. So I was invited to one of our instructors place which had a very beautiful and heritage architecture, ate very tradional Vegetarian food. On this occasion they also have faire as community.

PCB MILLING

RUBBED COPPER PLATE WITH SAND PAPER

PCB MILLING

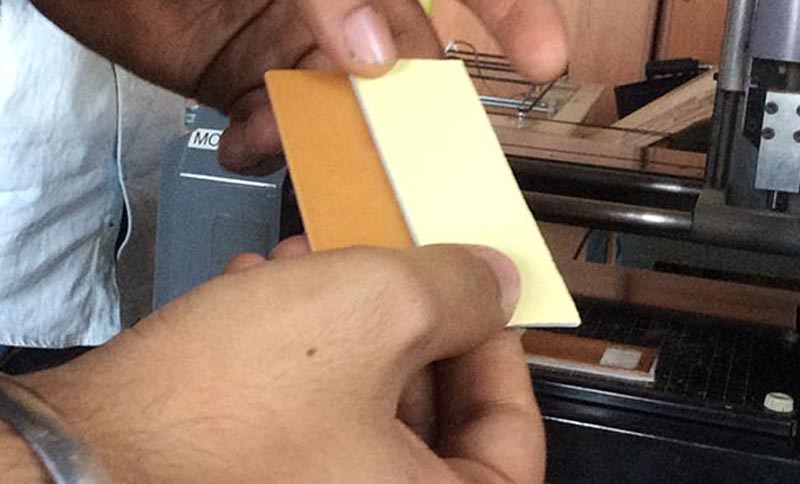

APPLIED DOUBLE SIDED TAPE

PCB MILLING

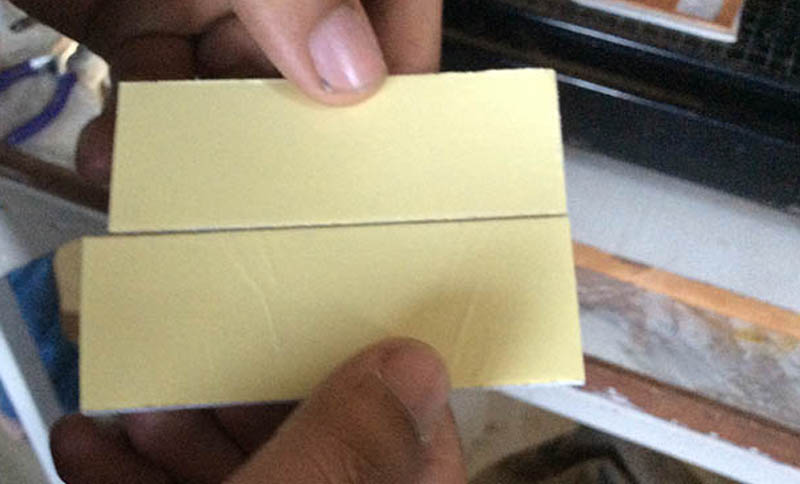

ALIGNED TAPE

PCB MILLING

READY TO SECURE ON BED

PCB MILLING

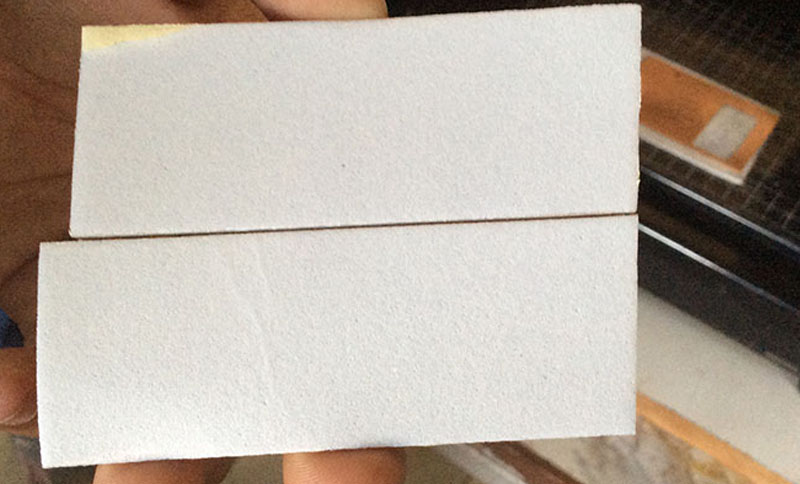

PEELED OFF THE LAMINATE

PCB MILLING

PLATE SECURED ON BED

PCB MILLING

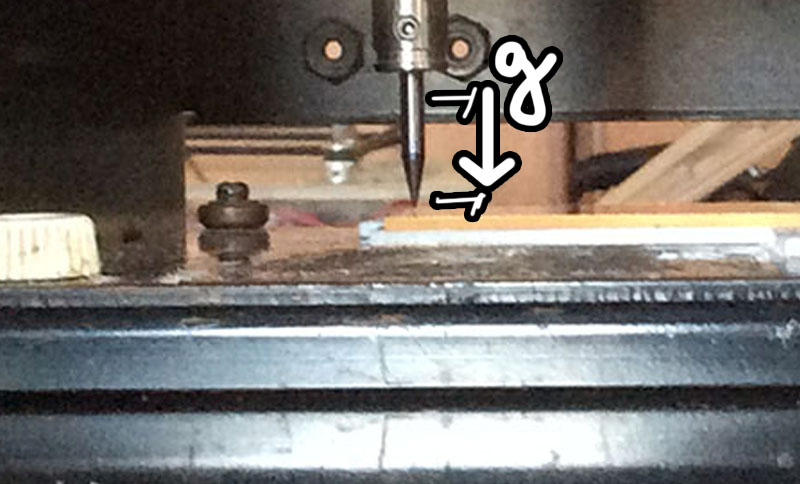

BROUGHT BIT CLOSE TO BOARD

PCB MILLING

LET GRAVITY MAKE THE FINAL ADJUSTMENTS

PCB MILLING

HAPPY MOMENT

PCB MILLING

DRILLED HOLE INTO THE PCB

PCB MILLING

STARTED SECURING MY COMPONENTS

PCB MILLING

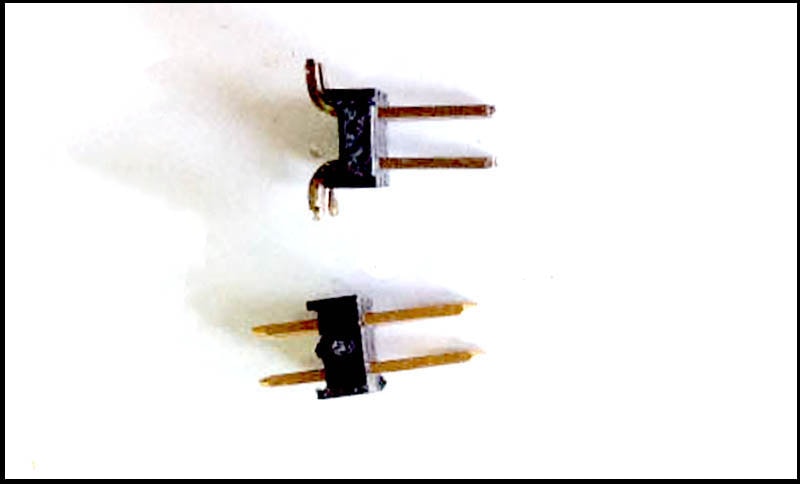

NOT SATISFIED WITH HOLE-REDRILLED

<-- Day 24

Day 25

[ Stuffing the Board ]

Day 26 -->

Today, its Vigyan Ashram's holiday as its their Village yatra (journey) where all the people belonging to that village meet each other coming from different places, pray as community and invite others to their home for lunch and dinner. So I was invited to one of our instructors place which had a very beautiful and heritage architecture, ate very tradional Vegetarian food. On this occasion they also have faire as community.

Today, its Vigyan Ashram's holiday as its their Village yatra (journey) where all the people belonging to that village meet each other coming from different places, pray as community and invite others to their home for lunch and dinner. So I was invited to one of our instructors place which had a very beautiful and heritage architecture, ate very tradional Vegetarian food. On this occasion they also have faire as community.- 1.Gathered all components

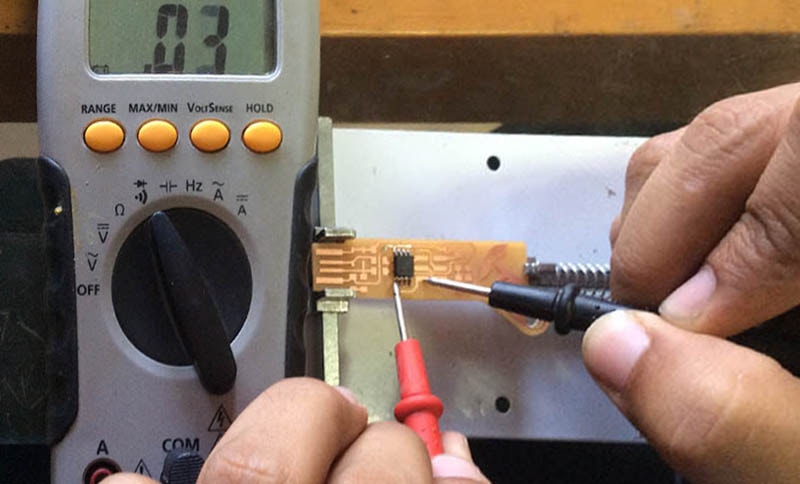

2. learnt how to stuff it and solder

3. Learnt importance of Flux and how to add and remove solder

4. Loved arranging the components while soldering

SOLDER TIME

SOLDERED IC FIRST-CHECKED CONTINUITY

SOLDER TIME

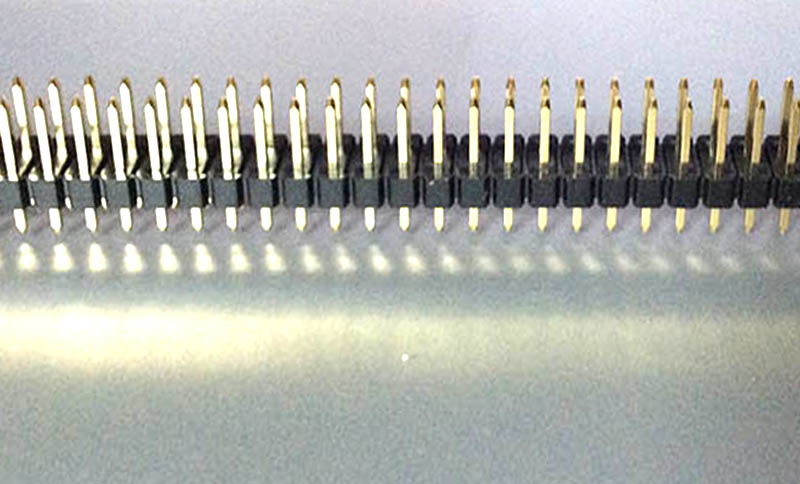

ADJUSTED HEADER PINS FOR SOLDERING

<-- Day 25

Day 26

[Programming time]

Day 27 -->

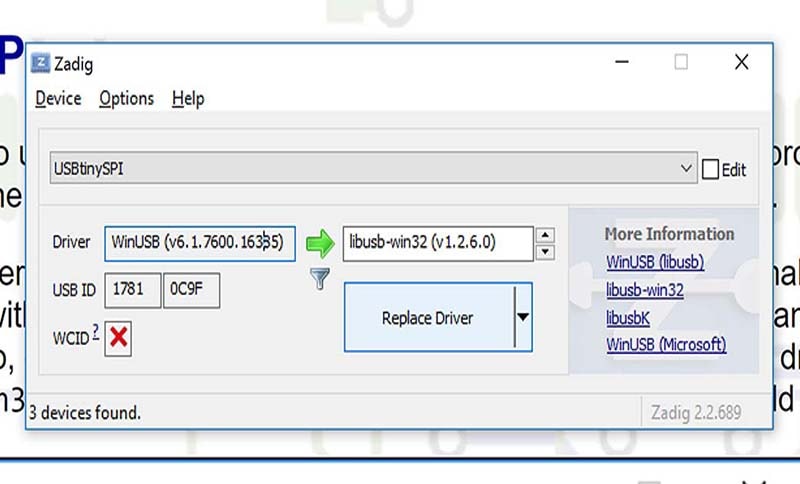

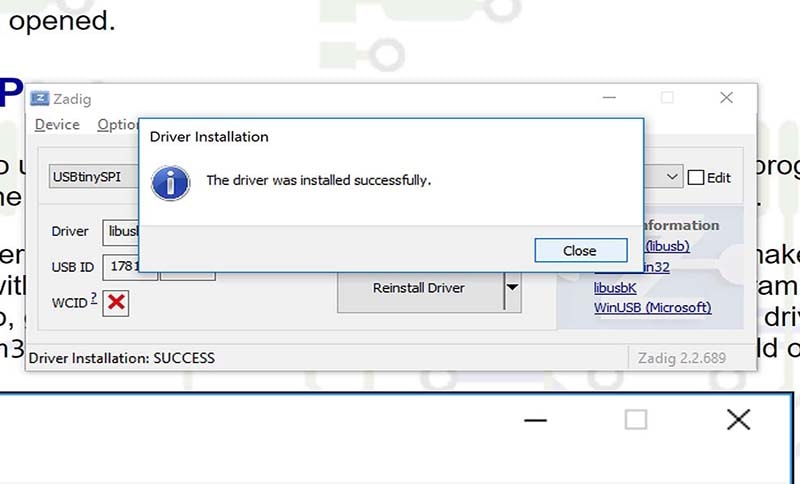

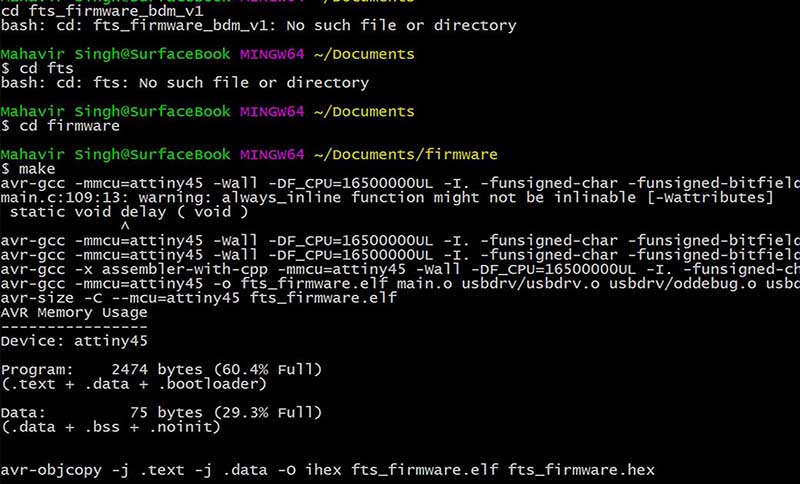

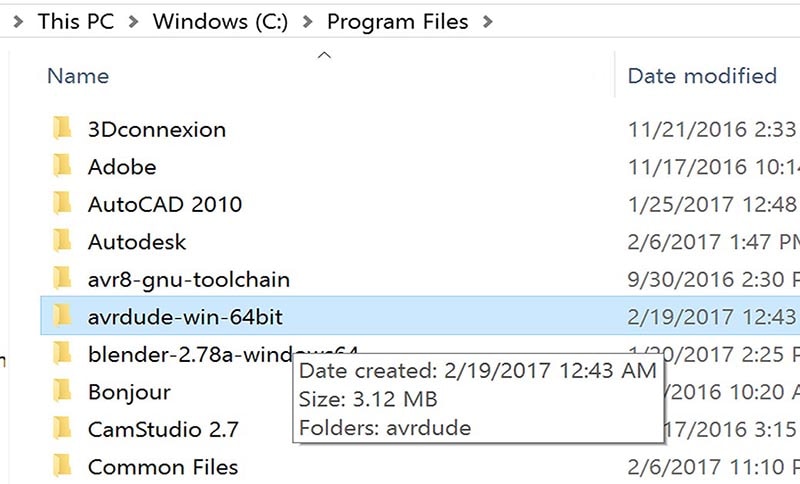

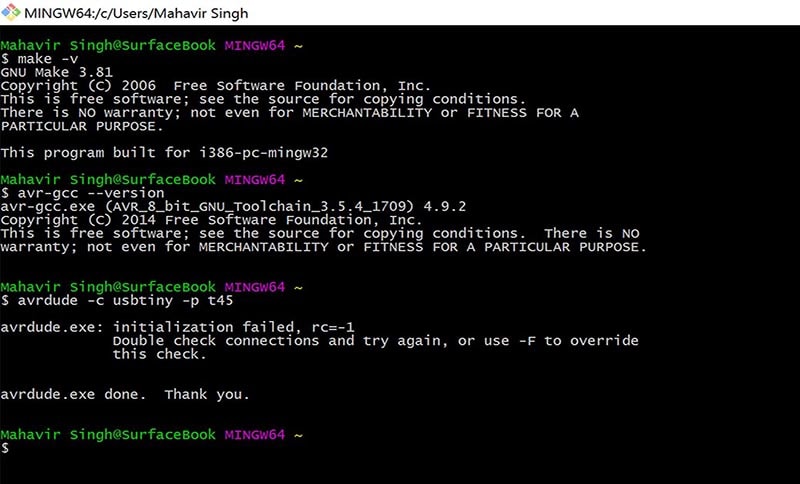

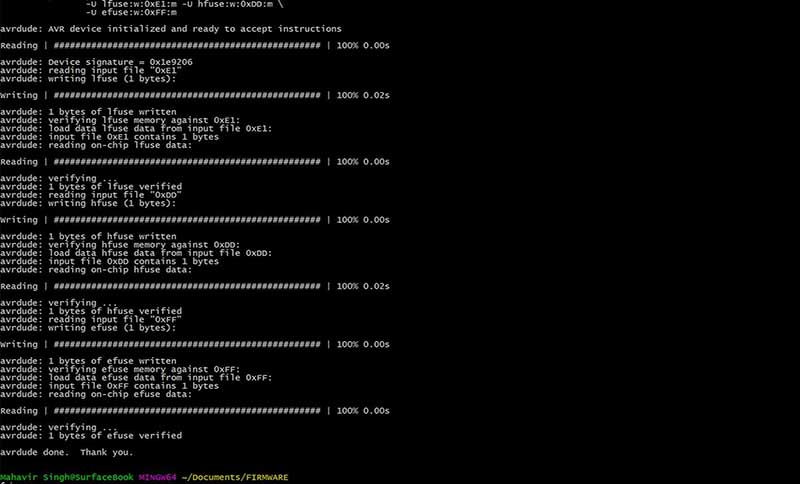

- Made it a point to try programming with windows as its mentioned in Brian's tutorial - Got lots of errors every step but figured it out slowly. - Installed softwares mentioned in Brian's tutorial

I liked this week as it forced me to not sit on laptop whole day designing and working but also do hands on work . I discussed with Yogesh ji my final project and how i plan to improvise it with time and use Shopbot before the given week so that i am able to figure out ideas to improve my final project. Nishtha made few designs which can be used for folding in group assignment as reference for all of us for our projects, so using 2 from that and designing 3-4 of mine i laser cut all of them and analysed which one go well easily for my Maker turban.

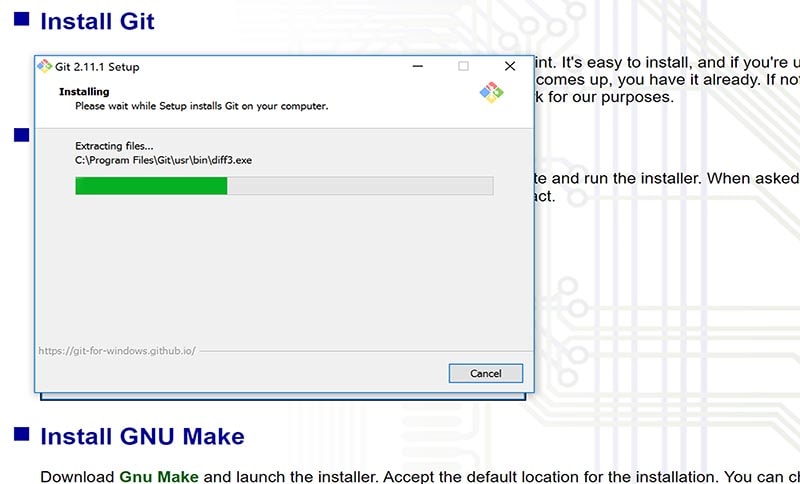

STEP 1

INSTALLED GIT

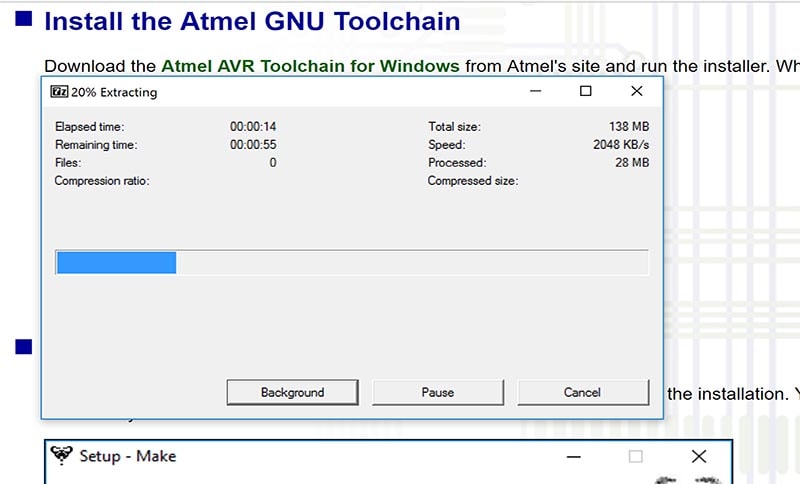

STEP 2

INSTALLED ATMEL GNU TOOLCHAIN

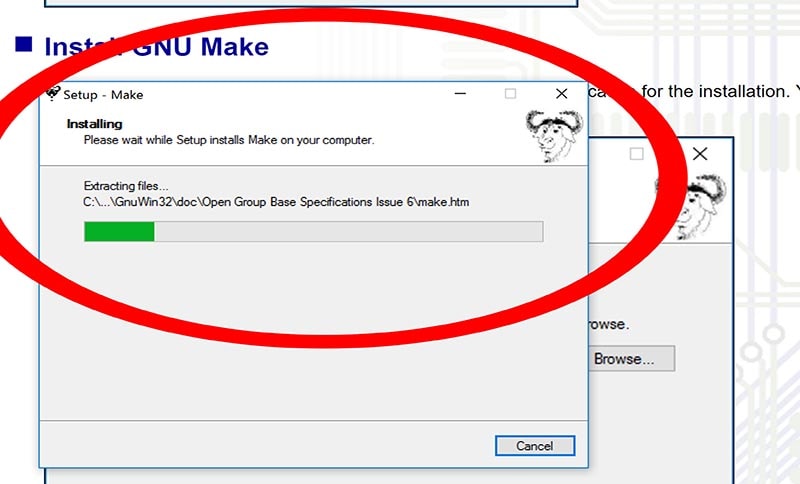

STEP 3

INSTALLED GNU MAKE

STEP 4

INSTALLED ATMEL STUDIO

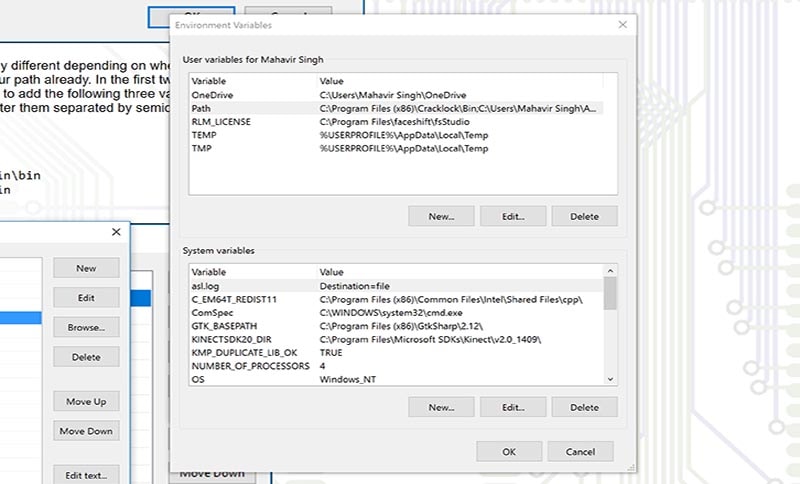

STEP 5

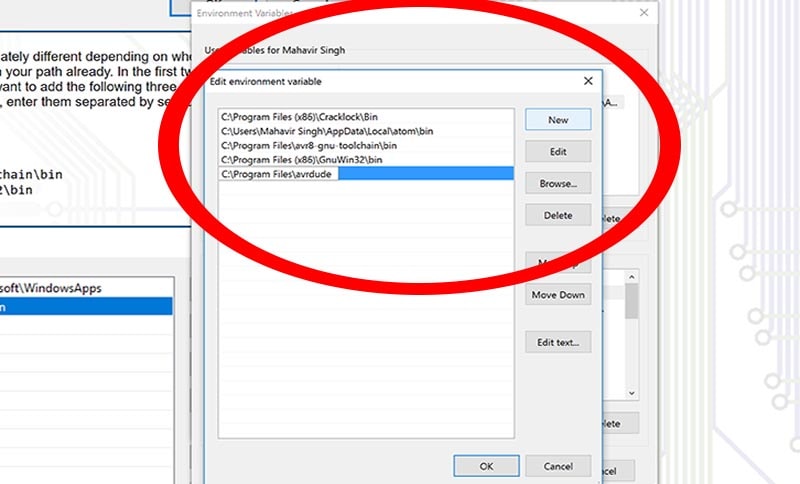

ACCESSED ENVIRONMENT VARIABLE

STEP 6

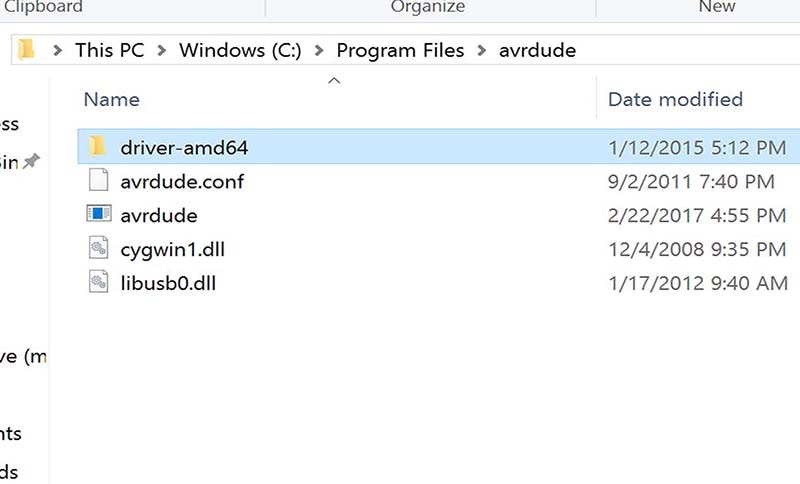

SET PATH IN ENVIRONMENT VARIABLE

<-- Day 26

Day 27

[Giving Windows a try]

Day 28 -->

I liked this week as it forced me to not sit on laptop whole day designing and working but also do hands on work . I discussed with Yogesh ji my final project and how i plan to improvise it with time and use Shopbot before the given week so that i am able to figure out ideas to improve my final project. Nishtha made few designs which can be used for folding in group assignment as reference for all of us for our projects, so using 2 from that and designing 3-4 of mine i laser cut all of them and analysed which one go well easily for my Maker turban.

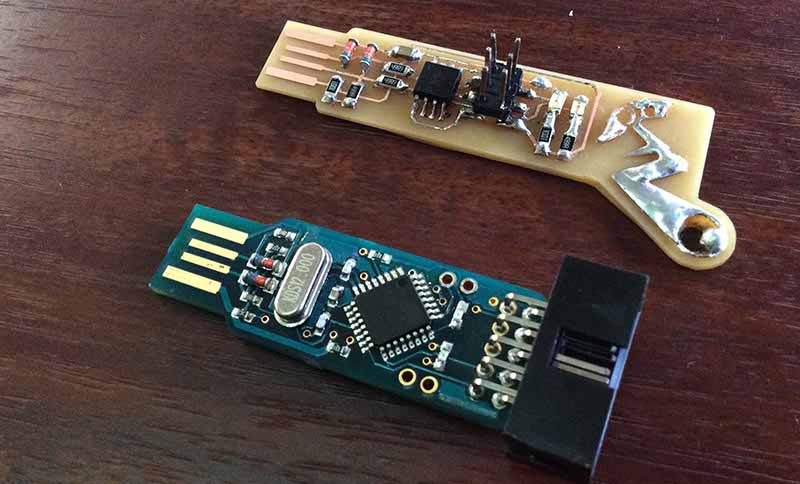

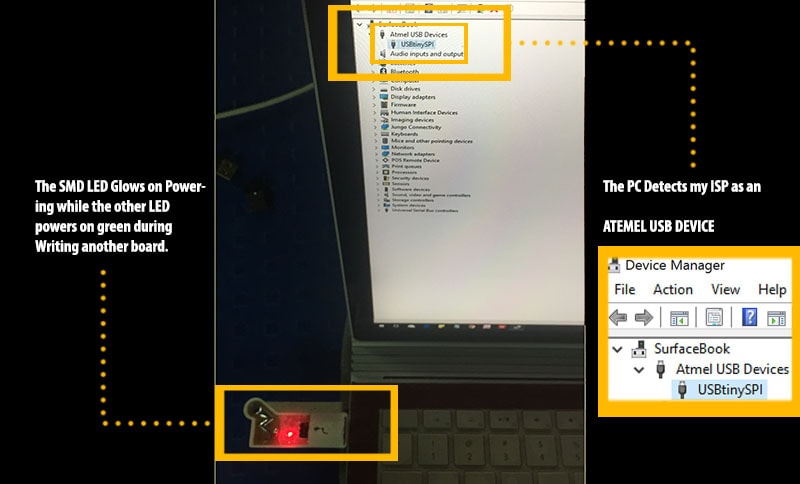

Step 1

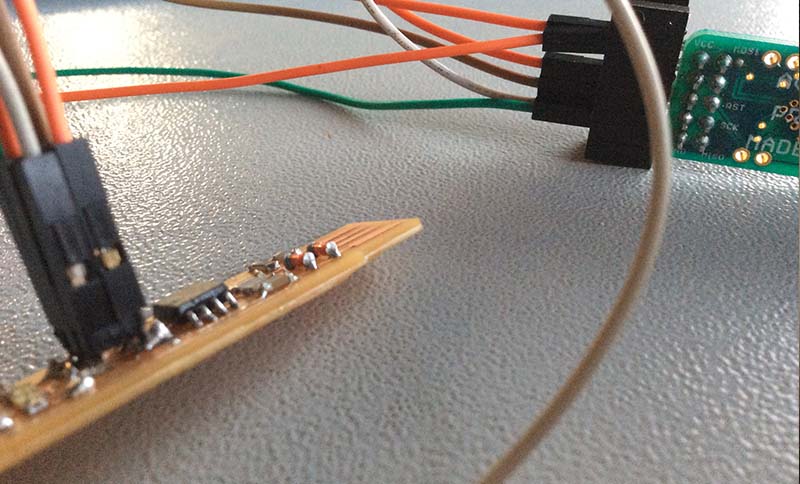

Trying a consumer programmer

Step 2

Understanding how to connect boards

Step 3

It lit up

<-- Day 27

Day 28

[ Thinking to try with UBUNTU]

Week 5 -->

I liked this week as it forced me to not sit on laptop whole day designing and working but also do hands on work . I discussed with Yogesh ji my final project and how i plan to improvise it with time and use Shopbot before the given week so that i am able to figure out ideas to improve my final project. Nishtha made few designs which can be used for folding in group assignment as reference for all of us for our projects, so using 2 from that and designing 3-4 of mine i laser cut all of them and analysed which one go well easily for my Maker turban.

STEP 1

WEEK 4

STEP 2

WEEK 4

STEP 3

WEEK 4

STEP 4

WEEK 4

STEP 5

WEEK 4

STEP 6

WEEK 4

STEP 7

WEEK 4

STEP 8

WEEK 4

STEP 9

WEEK 4

STEP 10

WEEK 4

STEP 11

WEEK 4

STEP 12

WEEK 4

STEP 13

WEEK 4

STEP 14

WEEK 4

STEP 15

WEEK 4

STEP 16

WEEK 4

STEP 16

WEEK 4

- Get link

- X

- Other Apps

Comments

Post a Comment